International projects

International projects STCU 5513

STCU 5513 Technological methods

Technological methods

Several technological methods for synthesis of SiO2:C composite materials are used:

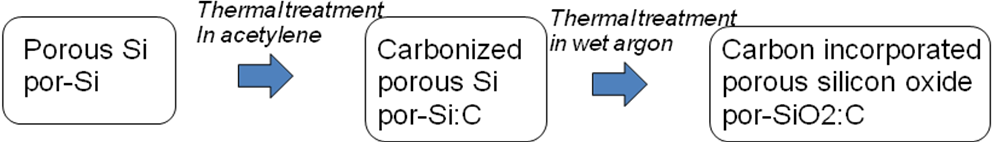

(1) carbonized nano-porous silicon oxide (por-SiO2:C) layers are fabricated by electrochemical etching of monocrystaline silicon wafers followed by successive thermal carbonization in acetylene flow and oxidation by water vapor;

|

Scheme of the procedure for fabrication of light-emitting por-SiO2:C layers |

|

|

|

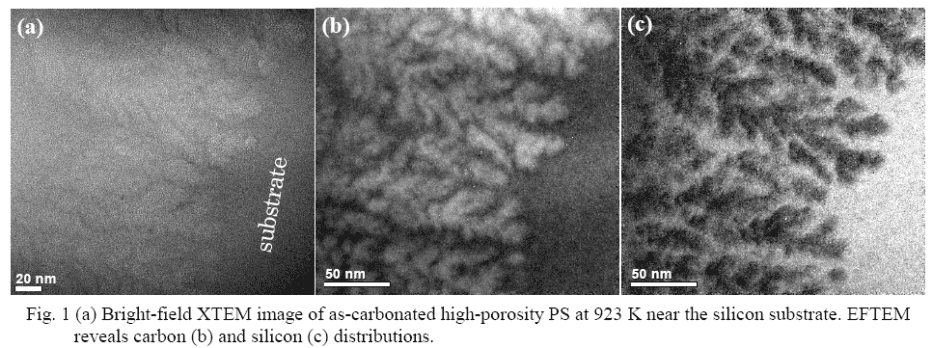

TEM image of por-SiO2:C layer and real photo of light emission of such kind of material |

|

|

|

|

(2) SiO(x)C(x):H thin films are fabricated by low-temperature oxidation of carbon-rich a-SiC:H thin films deposited by magnetron sputtering of Si or SiC target in argon/hydrocarbon gas mixture. After oxidation in oxygen flow at temperature 500-600 oC these films excibite white light photoluminescence.

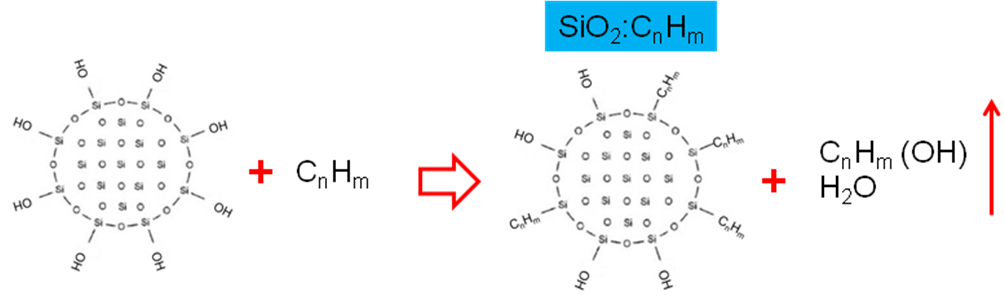

(3) SiO2:C nano-powders synthesized by chemical treatment of fumed nano-silica precursor (a-SiO2:H nano-powder) followed by thermal annealing in inert atmosphere;

Chemical treatment is performed so that to replace hydroxyl (-OH) groups with hydrocarbon groups (for example methyl groups, as shown in the picture).

|

Schematic ilustration of formation of SiO2:CnHm precursor powder |

|

|

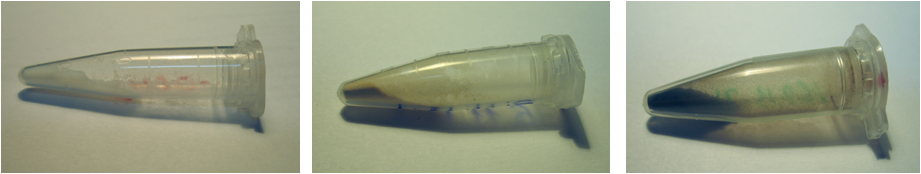

Following thermal annealing of silica-hydrocarbon powder SiO2:CnHm at temperature above 400 oC result in dehydrogenatetion of hydrocarbon radicals and carbon precipitation. Proper treatment results in formation of SiO2:C material that emits strong white light under excitation by violet or UV radiation

|

Evolution of the color of the powder with increase of the treatment temperature |

|

|

|

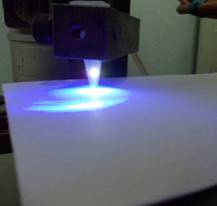

Photoilustration of light emission from SiO2:C powder under 408 nm LED |

|

|

Back to Top

|